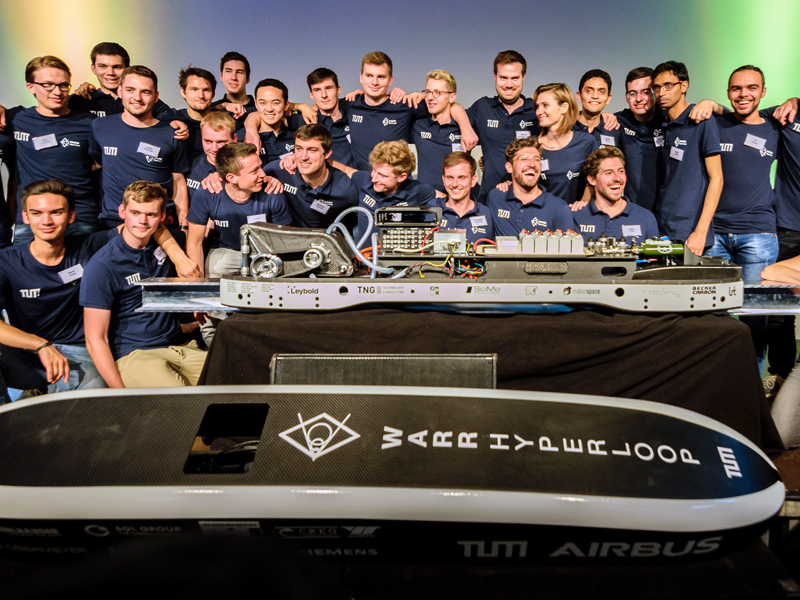

WARR Hyperloop team presents new streamlined pod

The pod sheds some weight

SpaceX founder Elon Musk launched the "Hyperloop Pod Competition" in 2015. The Hyperloop is a concept for a high-speed train which moves at close to the speed of sound in a tube containing a partial vacuum. Teams of students from around the world were called on to create designs for the pod, the cabin capsule which is to transport passengers. The pod of the first WARR Hyperloop team won the main prize for the fastest capsule as well as the Best Performance in Flight prize.

While the first competition focused mainly on scalability and design, in the second competition the victor will be chosen based solely on the maximum speed achieved. The new WARR Hyperloop team's concept had already qualified for the final in March of this year. The 30 students from eleven different nations have been working on the new pod for months and will now present it to the public for the very first time.

New pod weighs only 70 kilograms

In order to attain the highest possible speeds, the team developed its own drive system using a 50 kilowatt electric motor. They also implemented pneumatic muscles that press the drive-wheel against the track for optimized power transmission. The system is comparable to the spoiler on a race car which pushes the car down onto the road, preventing wheelspin. The pad's drive system accelerates it to a maximum speed of 350 km/h. Furthermore the young inventors emphasized lightweight construction, creating the entire structure out of carbon fiber. The pod weighs a total of only 70 kilograms.

The brake system uses four pneumatic brake calipers which can still be activated even in case electric power is lost. When the brakes are fully applied at 350 km/h, the pod comes to a standstill in only five seconds. A built-in stabilization system that always keeps the pod at the center of the tube also ensures optimum travel through the tubes. The vehicle is equipped with 38 different sensors that provide relevant information such as position and temperature to various components of the capsule during travel. The data are processed by a specially developed and custom-made electronic system.

In only a few weeks the 30-member team will take the pod to the SpaceX corporate campus in California to compete against teams from throughout the rest of the world in the 1.25 kilometer long testing tube segment.

Technical University of Munich

Corporate Communications Center

- WARR Hyperloop Team/S. Reiffert

- stefanie.reiffert@tum.de

- presse@tum.de

- Teamwebsite