Central Car Server (CeCaS) for highly automated vehicles

Software architecture for future cars

To ensure that the cars of the future can travel safely and reliably on roads regardless of environmental conditions, vast amounts of data must be processed. The data are collected in real time from sensors in the vehicle while driving and from databases and/or simulations on test benches during vehicle development. “For autonomous driving, the data recorded by the vehicle itself is combined with data from permanently installed cameras, lidars or radar sensors on sign bridges or from other nearby vehicles. That would be the maximum amount of information you could get,” says Knoll, head of the TUM Chair of Robotics, Artificial Intelligence and Real-Time Systems.

Ad-hoc data analysis

Over the past three years, researchers at TUM and various partners from the automotive and chip industries have developed a suitable vehicle architecture that evaluates and uses the data on an ad-hoc basis – as part of the ‘Central Car Server’ (CeCaS) research project funded by the Federal Ministry of Research, Technology and Space (BMFTR). A centralized and entirely software-based architecture of this kind will be required for vehicle generations from 2033 onwards.

The advantages in detail:

(1.) Scenarios can be tested realistically in simulations

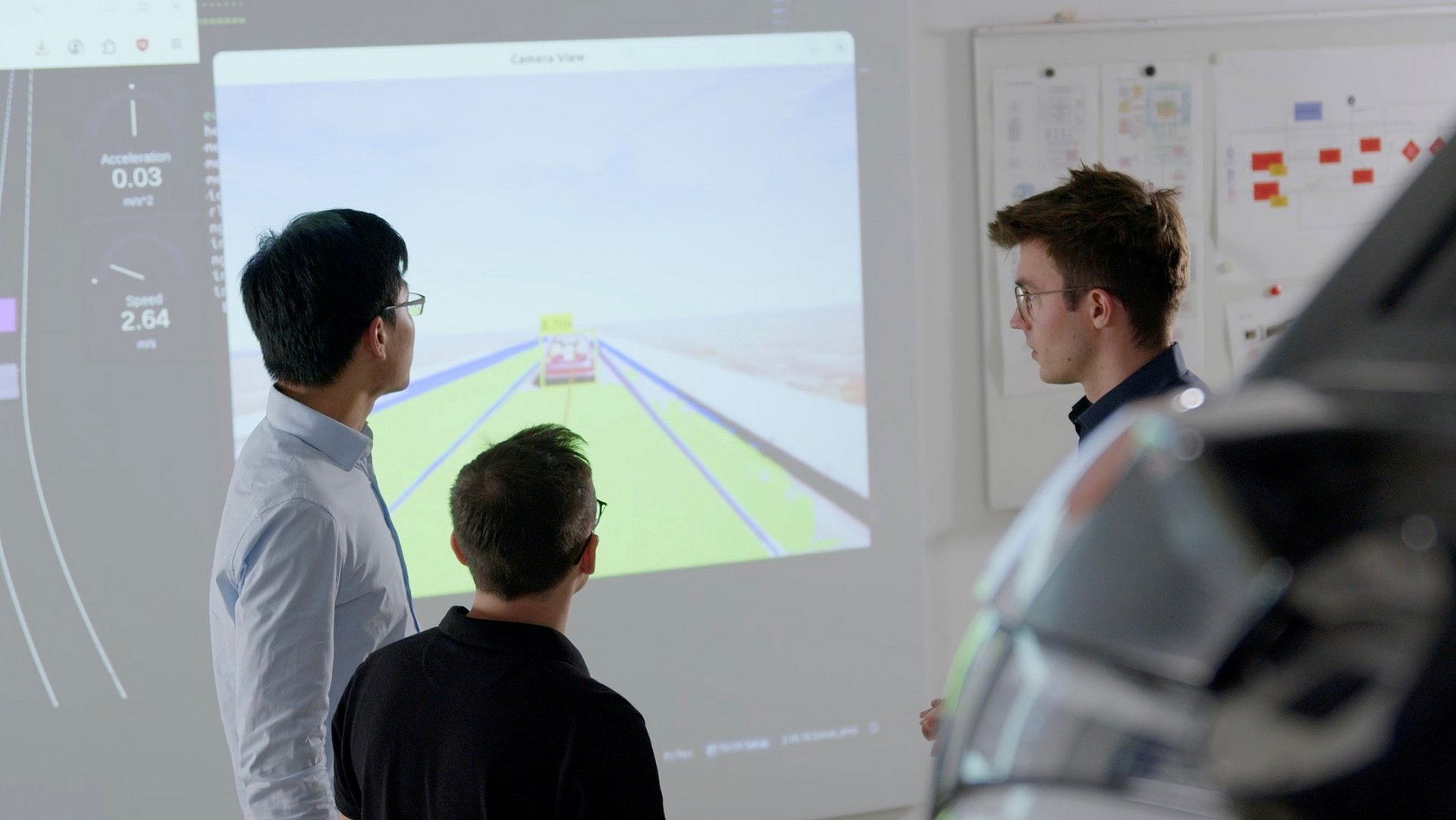

In reality, vehicles are not yet fully capable of handling many traffic and weather conditions that they encounter. To address this, researchers have created a simulation environment in which a wide range of scenarios can be generated with the aid of powerful graphics chips. After training, the vehicle has the knowledge to cope with the given situation ‘on board’. The scenarios can also be made available to users from the automotive industry and research via open source access.

(2.) Drastic cost savings through centralized and standardized data processing

Conventional vehicles often use more than a hundred individual control units. Versatile, programmable high-performance computers such as those used in the CeCaS concept will largely replace them in the future. This will eliminate the need for many connecting cables between control units, make installation easier and reduce costs. Above all, however, it will be possible to add new functionality purely through software upgrades. And, as with mobile phones, the software development can be customized by customers.

(3.) A digital twin allows all functions to be assessed on the test bench

The TUM test bench allows vehicles to be securely clamped in place with all axles and wheels for testing. This means that not only driver assistance systems, anti-lock braking systems and new emergency braking assistants can be tested. “Using a digital twin of the vehicle, we can also import scenarios and perform live testing on the test bench,” explains TUM researcher Alois Knoll. In addition, scenarios from real-world accidents involving autonomous or semi-autonomous vehicles can be imported and used for training – without anyone being harmed in the process.

Artificial intelligence: software created effortlessly

For TUM Professor Knoll, a key advantage of the future vehicle architecture is that it will accelerate development processes and thus innovation as well. As TUM research results within the framework of the CeCaS project show, software can be developed ever more quickly with the help of artificial intelligence and generative language models. Specifications are almost always available in text form. And these reflect the behavior of technical devices. TUM researchers have shown that language models can process specifications as long as they are consistent, complete and free of contradictions, which in turn can be checked by AI. This allows new software code to be created in seconds, virtually by design. However, this requires the entire architecture in the vehicle to be compatible. Knoll: “Understanding cars as software-defined vehicles, i.e. software platforms, is simply necessary in order to remain competitive in the vehicle market in the future.”

K. Lebioda, N. Petrovic, F. Pan, V. Zolfaghari, A. Schamschurko, A. Knoll; Are Requirements Really All You Need? Using LLMs to Generate Configuration Code: A Case Study in Automotive Simulations; 8-2025; https://ieeexplore.ieee.org/document/11122468;

S. Kirchner, A. C. Knoll; Generating Automotive Code: Large Language Models for Software Development and Verification in Safety-Critical Systems; IEEE Intelligent Vehicles Symposium (IV 2025), Cluj-Napoca, Romania; doi.org/10.1109/IV64158.2025.11097503; 6-2025

N. Petrovic, F. Pan, V. Zolfaghari, K. Lebioda, A. Schamschurko, A. Knoll; GenAI for Automotive Software Development: From Requirements to Wheels; DTF Symposium 2025; arxiv.org/abs/2507.18223; 10-2025

Chengdong Wu, Sven Kirchner, Nils Purschke, Alois C. Knoll; ViL-TUM: A Testbench-Based Vehicle-in-the-Loop Test Method for Central Car Server Validation; DTF Symposium 2025, 10-2025

The TUM test bench is the only one of its kind being used in research institutions in Germany. Unlike a roller test bench, where the vehicle is rolled onto a test bench and then drives on the spot, as is the case with the TÜV testing organizations in Germany and Austria, the vehicle's tires are removed before it is securely bolted down. The advantage of this is that braking, acceleration, cornering and driving in all weather conditions can be tested almost as if in real life. Test bench simulations can be used to test and check both the vehicle electronics and the software of the ‘software-defined vehicle’. Test bench available on request: Marie-Luise Neitz, email: neitz@in.tum.de

Central Car Server (CeCaS) research project: The goal of this research project involving more than 30 partners from research and industry, which received over EUR 88 million in funding over the last three years, including EUR 46 million from the Federal Ministry of Research, Technology and Space (BMFTR), was to create an automotive supercomputing platform as a central computing unit for highly automated vehicles. A core component was a software-based and centralized vehicle architecture. Under the consortium leadership of the chip manufacturer Infineon, TUM worked on the vehicle architecture for the next-but-one generation of cars and the test setup, among other aspects. Further information: https://www.elektronikforschung.de/projekte/mannheim-cecas

Video: An important component of the research project is a software-defined test bed, for which research partner and VW subsidiary Cariad provided the ID.BUZZ electric bus, which was mounted on the test bench as a ‘functional vehicle’. This allows the testing of real-world driving functions commonly seen in traffic. Scenarios that have led to accidents involving autonomous or semi-autonomous vehicles in the past can also be tested in this way so that malfunctions are rectified before the vehicle is approved for road use. Watch the video: www.youtube.com/watch

Technical University of Munich

Corporate Communications Center

- Andreas Schmitz

- presse@tum.de

- Teamwebsite

Contacts to this article:

Prof. Alois Knoll

Chair of Robotics, Artificial Intelligence and Real-Time Systems

Technical University of Munich (TUM)

k@tum.de