Comparison of mechanical and geometric properties for industry and development

Uniform reference system for lightweight construction methods

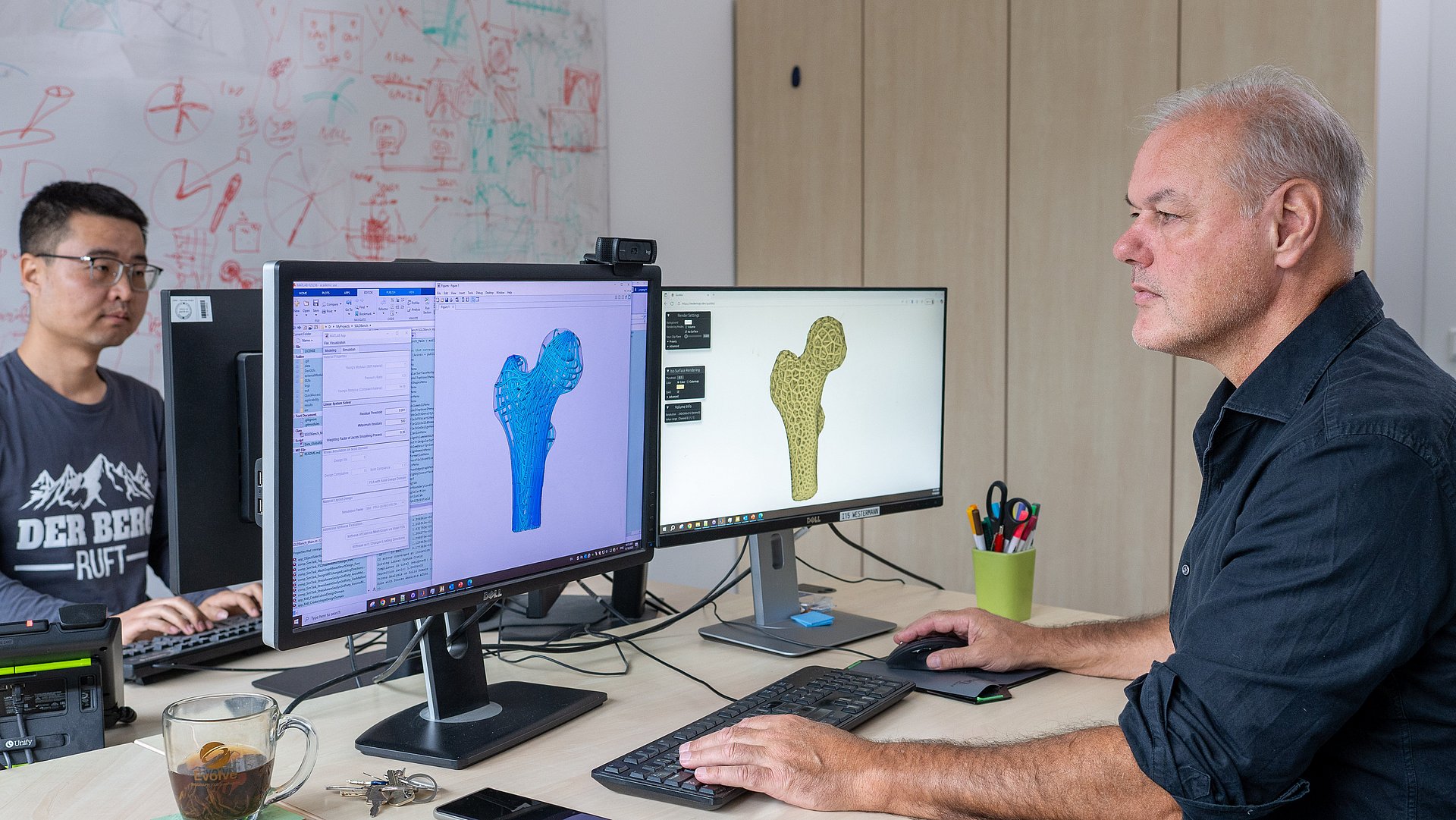

Lightweight components are generally designed with computer-based methods before being manufactured. There are various common methodologies. Because they use different physical and mathematical descriptions, however, direct comparisons are difficult. Moreover, the highly complex computation methods limit them to low spatial resolutions. With their Stress-Guided Lightweight 3D Designs (SGLDBench) benchmark, the researchers have succeeded in overcoming these serious obstacles.

SGLDBench standardizes lightweight design methods

SGLDBench permits six reference strategies such as classical topology optimization, porous infill structures or lattice-based layouts to be applied to arbitrary components with user-defined boundary conditions and compared using 3D simulations. It incorporates such parameters as stiffness-to-weight, stress fields and deformability as well as information on how the component or structure is connected to or positioned in its surroundings. This enables users to create designs with different resolutions and material use while evaluating the mechanical and geometric characteristics.

The new benchmark has potential applications in many areas: for example, it enables testing of various design variants for hip implants followed by customized manufacturing. In the automotive and aerospace industries, the benchmark will also help to make parts even leaner. In those areas, weight savings lead to improved energy efficiency. At the same time, the structures must be designed to meet stringent safety standards in their ability to withstand shocks and vibrations.

Benchmark allows more than 100 million simulation elements

“With SGLDBench we have created a transparent benchmark for lightweight design,” says Rüdiger Westermann, Professor for Computer Graphics and Visualization at the TUM School of Computation, Information and Technology. “That will not only help researchers with the classification of methods, but will also give companies a tool for reaching well-founded decisions in product development.” At present, SGLDBench can perform simulations with more than 100 million elements on an affordable desktop computer in much faster times than commercial products.”

Among the methods making this possible, the researchers used new approaches in particular for the efficient solution of large systems of equations for stress simulations and optimized them for conventional computer architectures.

- Wang, J., Aage, N., Wu, J., Sigmund, O., Westermann, R. Efficient large-scale 3D topology optimization with matrix-free MATLAB code. Struct Multidisc Optim 68, 174 (2025). https://doi.org/10.1007/s00158-025-04127-3

- Wang, J., Bukenberger, D. R., Niedermayr, S., Neuhauser, C., Wu, J., and Westermann, R. SGLDBench: A Benchmark Suite for Stress-Guided Lightweight 3D Designs, in IEEE Transactions on Visualization and Computer Graphics, vol. 31, no. 10, pp. 8609-8622 (2025). http://doi.org/10.1109/TVCG.2025.3573774

Technical University of Munich

Corporate Communications Center

- Julia Rinner

- presse@tum.de

- Teamwebsite

Contacts to this article:

Prof. Rüdiger Westermann

Technical University of Munich (TUM)

TUM School of Computation, Information and Technology

Chair for Graphics and Visualization

westermann@tum.de