Innovative light-weight torque vectoring transmission for Visio.M

Perfect torque distribution for safe driving

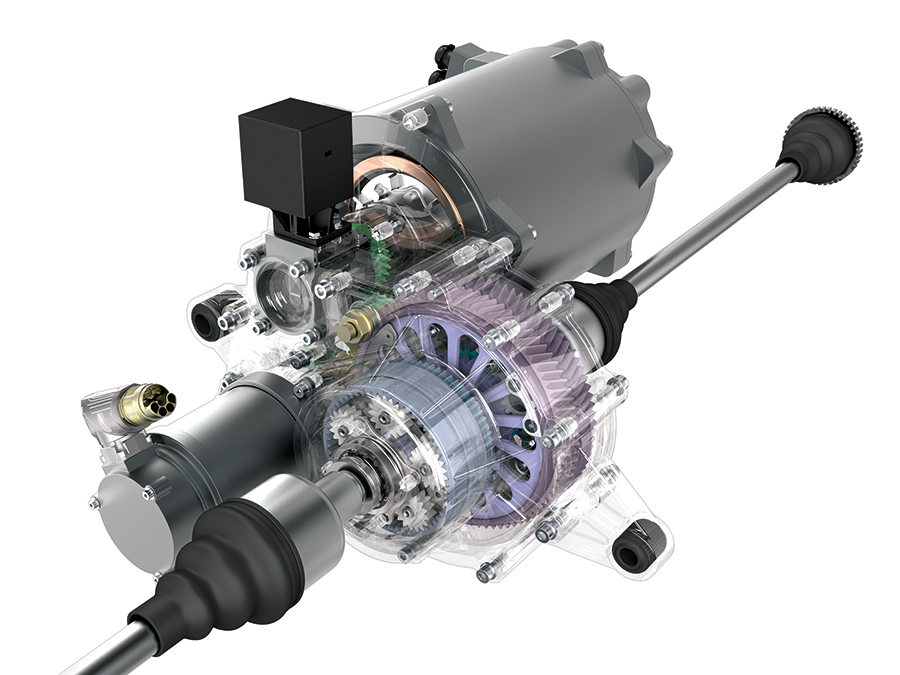

A limiting factor for the driving range of electric vehicles is the amount of energy supplied by the batteries. To recoup as much braking energy as possible, engineers at the Gear Research Center (FZG) at the TU München have developed a light-weight torque vectoring transmission for electric vehicles.

“While drive torque is normally distributed 50/50 to the wheels of the drive axle, our torque vectoring system doses the torque between the wheels as required,” explains engineer Philipp Gwinner from FZG. “This also ensures particularly good drive dynamics.” When a vehicle accelerates in a curve, greater torque is applied to the outside wheel. The car steers itself into the curve. The result: greater agility and, at the same time, safer road handling.

Recovering braking energy in curves

Even more important to the researchers, however, is the efficient recovery of braking energy. Normally, brakes convert kinetic energy into heat. So-called recuperation systems can prevent this. They work along the principle of a bicycle dynamo, which converts energy tapped from the wheel into electrical energy. In the case of electric vehicles this energy can be used to recharge the batteries, thereby extending the driving range.

Unfortunately, in curves the recuperation of braking energy is limited since the inside wheel bears significantly less load than the outside wheel. The torque vectoring function adjusts the recuperation torque for both wheels individually. This increases vehicle stability while at the same time allowing more energy to be recovered.

Less weight, lower cost

Torque vectoring transmissions are used today in select top model cars and sports cars with combustion engines. Due to their high cost and additional weight torque vectoring transmissions have not found application in electric vehicles. The aim of the researchers was, thus, to optimize the transmission for small vehicles with electric drives.

Instead of the standard bevel gears used in differential transmissions, the engineers developed a spur gear differential in which additional torque can be applied from outside via a superimposed planetary gearbox. Using a small (in comparison to the drive motor) electric torque vectoring machine they can generate a large yaw moment at any speed to achieve the desired road handling dynamics.

The housing of the first prototypes are made of aluminum. To save even more weight, the aluminum housing will be replaced by a composite case made of aluminum and a fiber-reinforced synthetic. To reduce the forces acting on the housing without increasing gear noise, which is critical in electrical vehicles, the researchers have developed a special gearing free of axial forces. This and further construction element optimizations led to a reduction in gearbox weight of more than ten percent.

“The elegant thing about the torque vectoring transmission we have developed is that it not only has a higher recuperation level, and, with that, an increased driving range,” says Professor Karsten Stahl, Director of the FZG, “the transmission also improves road handling dynamics, driving pleasure and safety. The continuously improving optimization measures leave us optimistic that in the near future both the weight and cost will be able to compete with today’s standard differential transmissions.”

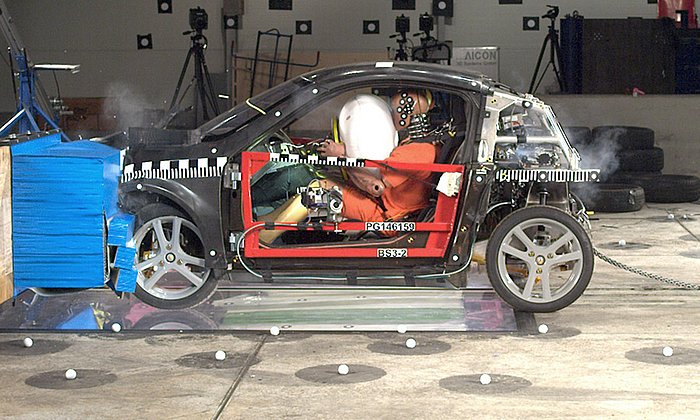

Participants in the Visio.M consortium are, in addition to the automotive companies BMW AG (lead manager) and Daimler AG, the Technische Universitaet Muenchen as a scientific partner, and Autoliv BV & Co. KG, the Federal Highway Research Institute (BAST), Continental Automotive GmbH, Finepower GmbH, Hyve AG, IAV GmbH, InnoZ GmbH, Intermap Technologies GmbH, LION Smart GmbH, Amtek Tekfor Holding GmbH, Siemens AG, Texas Instruments Germany GmbH and TÜV SÜD AG as industrial partners. The project is funded under the priority program "Key Technologies for Electric Mobility - STROM" of the Federal Ministry for Education and Research (BMBF) for a term of 2.5 years with a total budget of 10.8 million euro.

Contact:

Prof. Dr. Karsten Stahl

Technische Universität München

Institute for Machine Elements

Gear Research Centre (FZG)

Boltzmannstr. 17, 85748 Garching, Germany

Tel.: +49 89 289 15805 - E-mail - Internet

Technical University of Munich

Corporate Communications Center

- Stefanie Reiffert / Dr. Andreas Battenberg

- battenberg@zv.tum.de

- presse@tum.de

- Teamwebsite