Biomolecular film adheres to sensitive tissue and releases active ingredients

Multi-functional bandage helps wounds to heal

Conventional bandages may be very effective for treating smaller skin abrasions, but things get more difficult when it comes to soft-tissue injuries such as on the tongue or on sensitive surfaces like the intestines. What kind of material will adhere there without damaging the tissue or sticking to adjacent points? How can wounds be protected from external influences and bacteria? What kind of substance will allow cells underneath to close the wound, and then ultimately disappear without a trace?

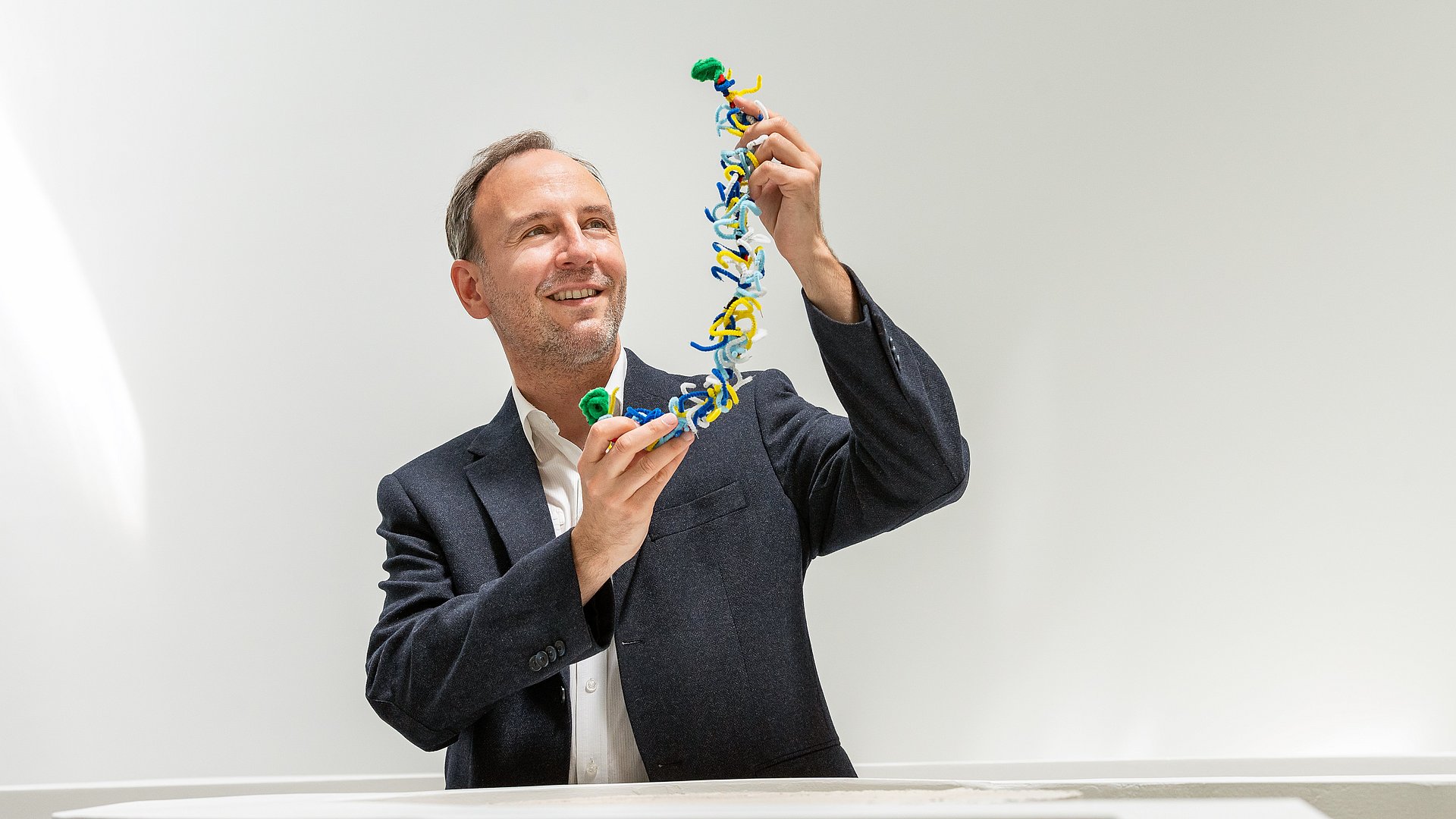

In spite of recent progress in developing materials addressing some of the specific requirements mentioned above, engineering a multifunctional all-in-one solution remains a challenge. A team led by Oliver Lieleg, Professor of Biomechanics at the Technical University of Munich (TUM), has developed a biopolymer film that combines a wide range of different functions at the same time. In a recently published study, the biomolecular “bandage” showed highly promising results and is ready to undergo further testing and tailoring.

A multi-functional bandage for sensitive surfaces

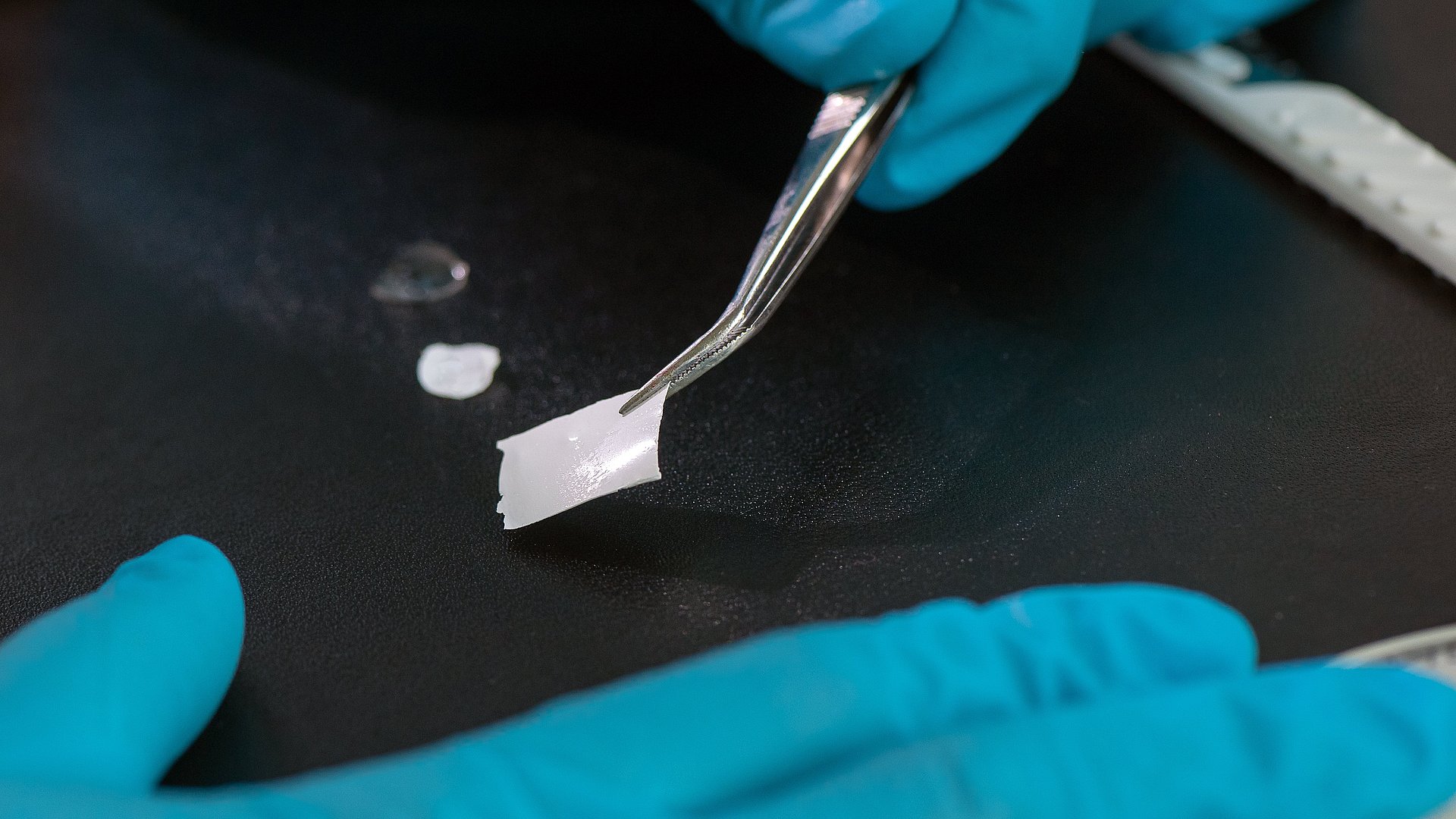

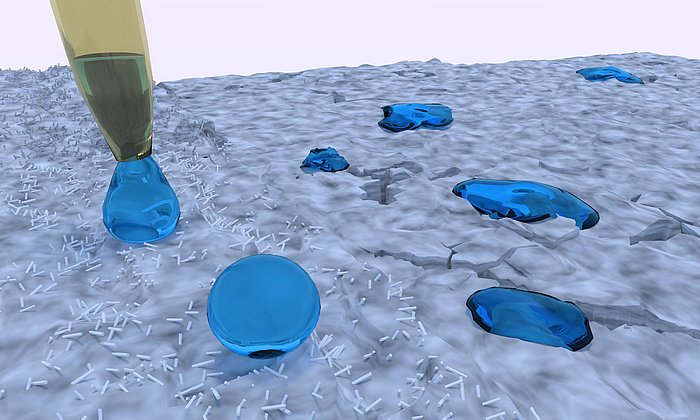

"When dry, the thin and flexible film can be picked up with tweezers and can easily be placed onto a wound. Upon contact with moist tissue, the bottom side of the film becomes squishy and sticky and adheres to the tissue by itself - without requiring additional fixation," says Ceren Kimna, first author of the study.

Lieleg and his team were able to show that these biomolecular bandages even adhere to smooth surfaces such as cartilage and moist tissue such as tongue without damaging the tissue surface. Covering a skin wound with this film even sped up the healing process.

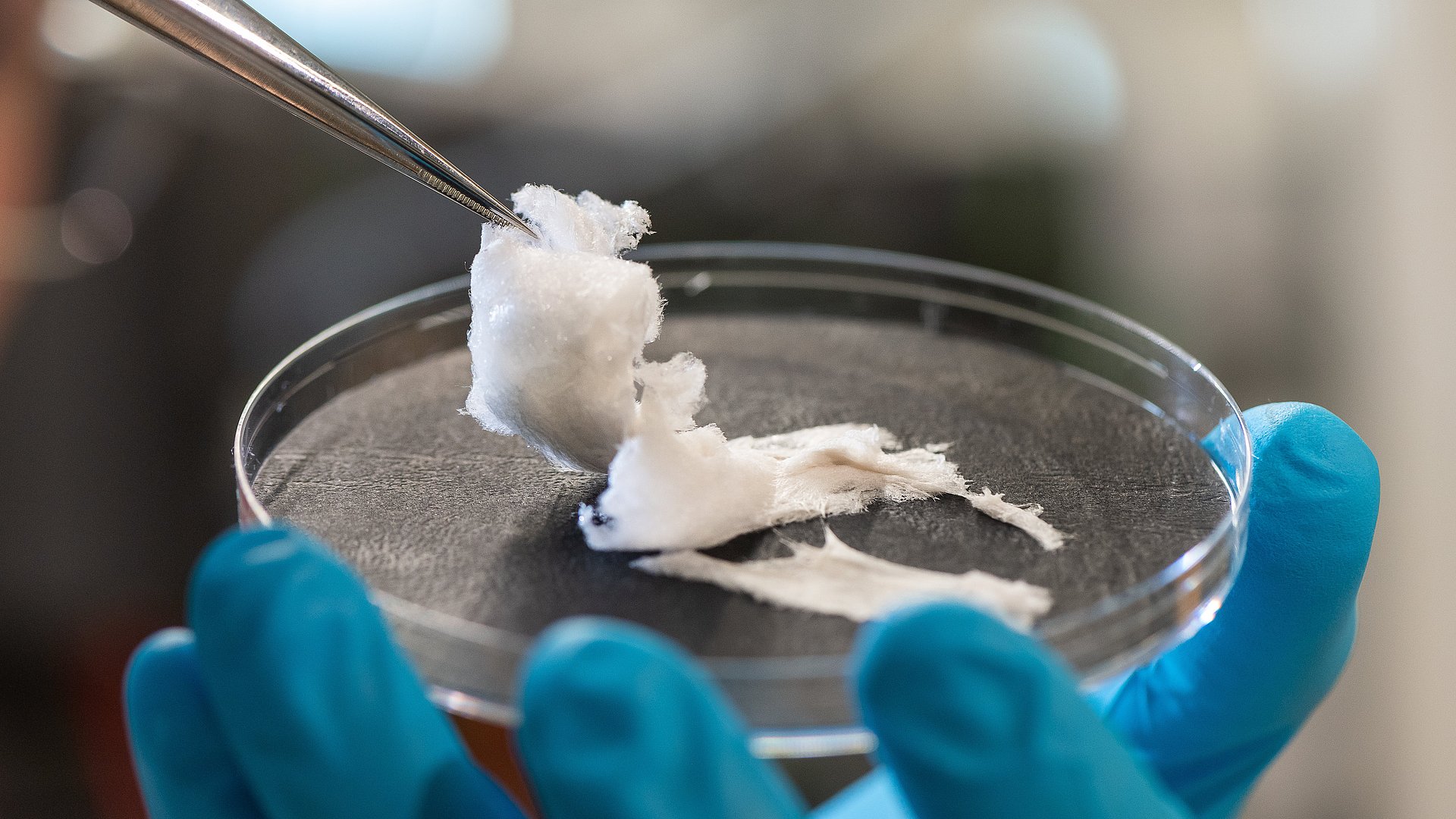

One particular goal of this study was to develop a material combination that completely dissolves by itself after several days without leaving any residues. The researchers were able to demonstrate this aspect in their experiments using high-resolution microscopy images of treated tissue samples.

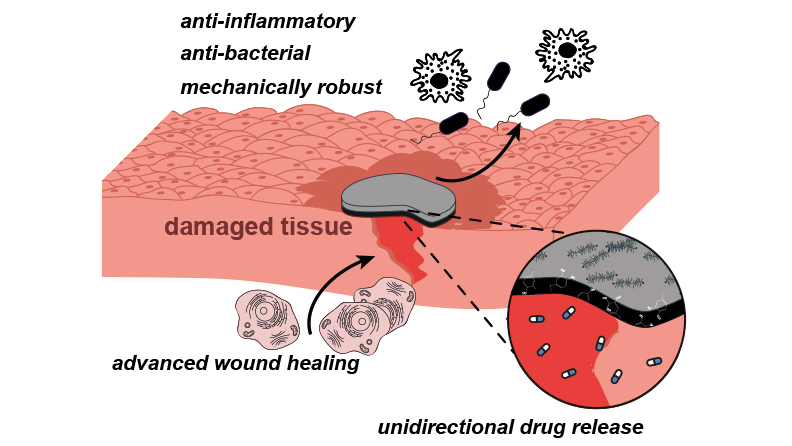

Different properties on the top and bottom side of the film

The film consists of two layers, making it possible to design each side such that it can perform special tasks. The top side consists of a biodegradable polymer which renders the thin film stable, and it also contains mucins.

"Mucins are molecules which occur naturally on mucous membranes of our bodies. Here, we have used them for the first time in biomolecular films to support wound healing. They provide important properties to protect the wound during the healing process: They have anti-bacterial properties, dampen inflammation and prevent unwanted cells from colonizing the wound," explains Professor Lieleg, who has been investigating these molecules for over a decade.

The bottom side of the film contains hyaluronic acid, a material well-known for its ability to bind water and to promote the healing of wounds. Other molecules are chemically bound to those hyaluronic acid macromolecules and make sure that the film becomes sticky upon contact with moisture, allowing the film to adhere to a tissue spontaneously.

When desired, active pharmaceutical ingredients such as antibiotics can also be integrated into the bottom layer. The two-layer structure makes it possible to release the active ingredients in only one specific direction: towards the wound.

Steps towards medical application

To date, the new material combination has been tested on various animal tissue samples. In addition, the team was able to demonstrate accelerated wound healing in animal tests, which is an important step on the way to clinical application. The suitability of the bandage for potential future use with human patients will be examined in additional studies.

In the future, these bandages could be optimized for selected application cases and particular types of tissue. Since the films completely dissolve in the presence of moisture, they could also be used in surgery to temporarily protect internal wounds which are afterwards inaccessible, for example after closure of an incision with a suture.

Ceren Kimna, Maria G. Bauer, Theresa M. Lutz, Salma Mansi, Enes Akyuz, Zuleyha Doganyigit, Percin Karakol, Petra Mela and Oliver Lieleg: Multifunctional ‘Janus-type’ bilayer films combine broad-range tissue adhesion with guided drug release. Advanced Functional Materials, April 2022. DOI: doi.org/10.1002/adfm.202105721

Prof. Oliver Lieleg and co-author Prof. Petra Mela are Principal Investigators at the Munich Institute of Biomedical Engineering (MIBE). MIBE is an Integrative Research Institute (IRI) within the Technical University of Munich (TUM) that fosters interdisciplinary cooperation and synergies between researchers from the broad field of Biomedical Engineering. At MIBE, researchers specializing in medicine, the natural sciences, and engineering join forces to develop new methods for preventing, diagnosing or treating diseases. The activities cover the entire development process – from the study of basic scientific principles through to their application in new medical devices, medicines and software.

Prof. Lieleg also carries out research at the TUM School of Engineering and Design, Department of Materials Engineering, and at the Center for Functional Protein Assemblies (CPA) at TUM.

The project was funded by the German Research Foundation (DFG) and the Munich Multiscale Biofabrication Network. Open access funding was enabled and organized by Projekt DEAL.

Technical University of Munich

Corporate Communications Center

- Carolin Lerch

- carolin.lerch@tum.de

- presse@tum.de

- Teamwebsite

Contacts to this article:

Prof. Dr. Oliver Lieleg

Technical University of Munich

Professorship of Biomechanics

Phone: +49 89 289 10808 (Press office)

oliver.lieleg@tum.de