TU München develops new sled for German skeleton pilot Anja Huber

Ergonomic racing sled

Skeleton athletes race down ice tracks head first at speeds of up to 150 kilometers per hour, only centimeters above the ice. During turns, both the athlete and the material are subject to centrifugal forces up to 5 g. Only a few hundredths of a second make the difference between victory and defeat.

To ensure that she would step up to the start in Sotchi with an optimal sled, the German skeleton athlete Anja Huber turned to Professor Veit Senner, who heads the Division of Sports Equipment and Materials at the TU München. Together with her long-term technician Wolfram Schweizer, the team designed a skeleton sled with material, aerodynamic and ergonomic characteristics custom tailored to Anja Huber.

In top-class sports, athletes and materials are pushed to the outer limits. Adding in the strict set of skeleton rules leaves very little leeway for improvement. “Our first task was thus to study the rules very carefully,” says Ilja Feldstein, doctoral candidate at the Institute of Ergonomics. Then the scientists took measurements. Using scan data they build precise 3D models of both the athlete and the sled she had been using.

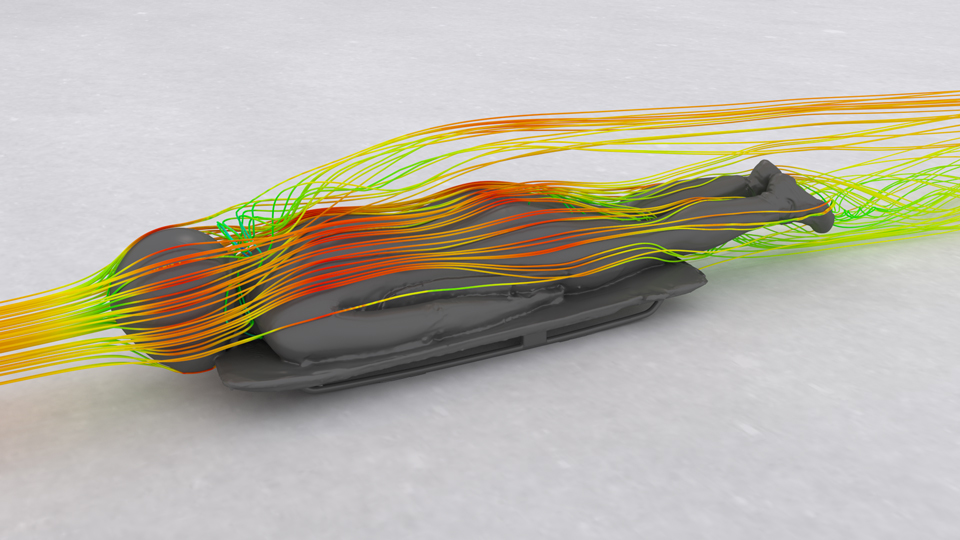

In collaboration with FluiDyna, a spin-off of the Institute of Aerodynamics, they designed a virtual model of an ice track on the computer. Now they could play through all conceivable variations and adaptations in a virtual airstream. Here, the scientists concentrated primarily on the optimal fit between the “saddle” and the athlete’s body. The aim was to obtain a smooth flow of air around the sled and rider to reduce aerodynamic drag as much as possible.

Since all components are strictly defined by the rules there are only very limited possibilities for improving the aerodynamics. A primary drain on energy comes form turbulences at edges and transition points. In Anja Huber’s new sled a pneumatic system now helps close the gaps between the athlete and her sled. In addition to an improved ergonomic and aerodynamic shape, the researchers developed a special anti-slip coating that holds the athlete firmly during her ride.

The regulations stipulate that the sleds are made of steel – materials like titanium or carbon are not allowed. Together with the Institute of Metal Forming and Casting of the TU München, the researchers tested different kinds of steel. For the saddle they chose a special-purpose steel used in the automotive industry. At their computers, the engineers calculated a pressing tool to form the saddle to fit perfectly to the athlete’s body in a single step. In this way the prescribed stiffness could be achieved with significantly lower weight. “Thanks to the reduced weight of the sled we were able to apply lead weights at positions favorable to the riding dynamics,” says Ilja Feldstein.

Following trials on the test track at Königssee and further fine tuning the new sled was presented to the acceptance committee. After an in-depth examination and further adaptations the sled received final approval. The project was financed by Anja Huber’s partner Red Bull.

Contact:

Prof. Veit Senner

Technische Universität München

Division of Sports Equipment and Materials

Boltzmannstr. 15, 85748 Garching, Germany

Tel.: +49 89 289 15364 – E-Mail – Internet