A sub-surface copper layer boosts activity of platinum electrodes

Efficiency of water electrolysis doubled

Yet wind turbines have to be switched off when there is too much energy in the grid. Alternatively excess energy could drive the splitting of water into hydrogen and oxygen. But so far, hydrogen is industrially produced mainly from natural gas, although this releases large amounts of the greenhouse gas carbon dioxide. But the process is still cheaper than the electrolysis of water.

Typically, platinum is applied as catalyst, in order to accelerate the conversion of water to hydrogen and oxygen. For the reaction to be as efficient as possible, intermediates must not adhere too strongly or too weakly at the catalyst surface.

Traditional electrodes bind intermediates too strongly

The team headed by Prof. Aliaksandr Bandarenka from the Department of Physics of Energy Conversion and Storage at TUM and Prof. Wolfgang Schuhmann from the Center for Electrochemical Sciences in Bochum now calculated how strongly intermediates must adhere to the electrodes, in order to most efficiently facilitate the reaction. The analysis revealed that traditional electrodes from platinum, rhodium and palladium bind the intermediates a bit too strongly.

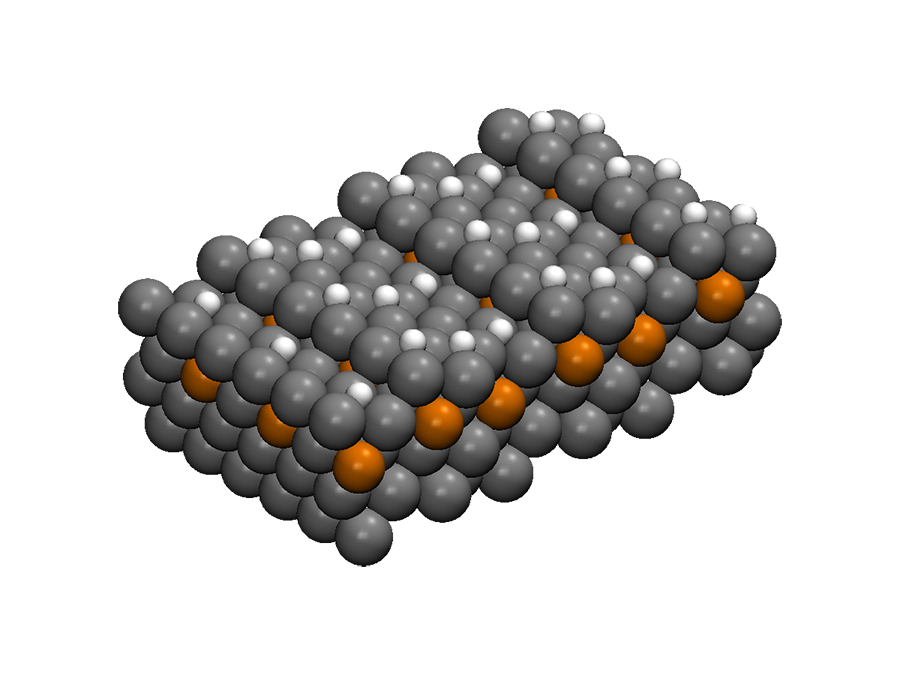

Thus the researchers modified the properties of the platinum catalyst surface by applying a layer of copper atoms. With this additional layer, the system generated twice the amount of hydrogen than with a pure platinum electrode. But only if the researchers applied the copper layer directly under the top layer of the platinum atoms. The group observed another useful side effect: the copper layer extended the service life of the electrodes, for example by rendering them more corrosion-resistant.

Water electrolysis could be powered by surplus electricity

Only four per cent of all hydrogen produced worldwide are the result of water electrolysis. As the electrodes used in the process are not efficient enough, large-scale application is not profitable. “To date, hydrogen has been mainly obtained from fossil fuels, with large CO2 volumes being released in the process,” says Wolfgang Schuhmann. “If we succeeded in obtaining hydrogen by using electrolysis instead, it would be a huge step towards climate-friendly energy conversion. For this purpose, we could utilise surplus electricity, for example generated by wind power.”

“In addition, the research on this reaction allows us to test, how well we can design catalyst surfaces by precisely positioning different metal atoms,“ adds Aliaksandr Bandarenka. „A knowledge many other catalytic processes might benefit from.”

The German Research Foundation has financed the project under the umbrella of the Clusters of Excellence RESOLV and Nanosystems Initiative Munich (NIM). Additional funding was supplied by the Helmholtz-Energy-Alliance “Stationary electrochemical storage systems and converters”.

Publication:

J. Tymoczko, F. Calle-Vallejo, W. Schuhmann, A. S. Bandarenka: Making the hydrogen evolution reaction in polymer electrolyte membrane electrolyzers even faster; Nature Communications, 10.03.2016 – DOI: 10.1038/NCOMMS10990

Contact:

Prof. Dr. Aliaksandr S. Bandarenka

Technical University of Munich

Physics of Energy Conversion and Storage

James-Franck-Str. 1, 85748 Garching, Germany

Tel.: +49 89 289 12531 – E-Mail – Web