Automated analysis of microplastics

Tracing invisible particles

Microplastics are everywhere in the environment. The tiny particles, with diameters of less than 5 millimeters, can also absorb and transport contaminants and toxins. “We urgently need analytical techniques to learn about the size, concentration and composition of these particles,” says Dr. Natalia Ivleva at the Chair of Analytical Chemistry and Water Chemistry at TUM. Together with her team, the scientist has developed a new process.

To be able to detect microplastic particles, the researchers had several hurdles to overcome: The first was the problem of low concentrations. River water, for example, contains massive amounts of suspended solids and fine sand, with plastic accounting for less than 1 percent of the particles. These particles must first be isolated before their concentrations and ultimately their chemical composition are determined. Previous methods have relied on the analysis of the residues that are released when the samples are heated. With that approach, however, it is not possible to determine the number, size and shape of the plastic particles.

Plastics can be identified through light scattering

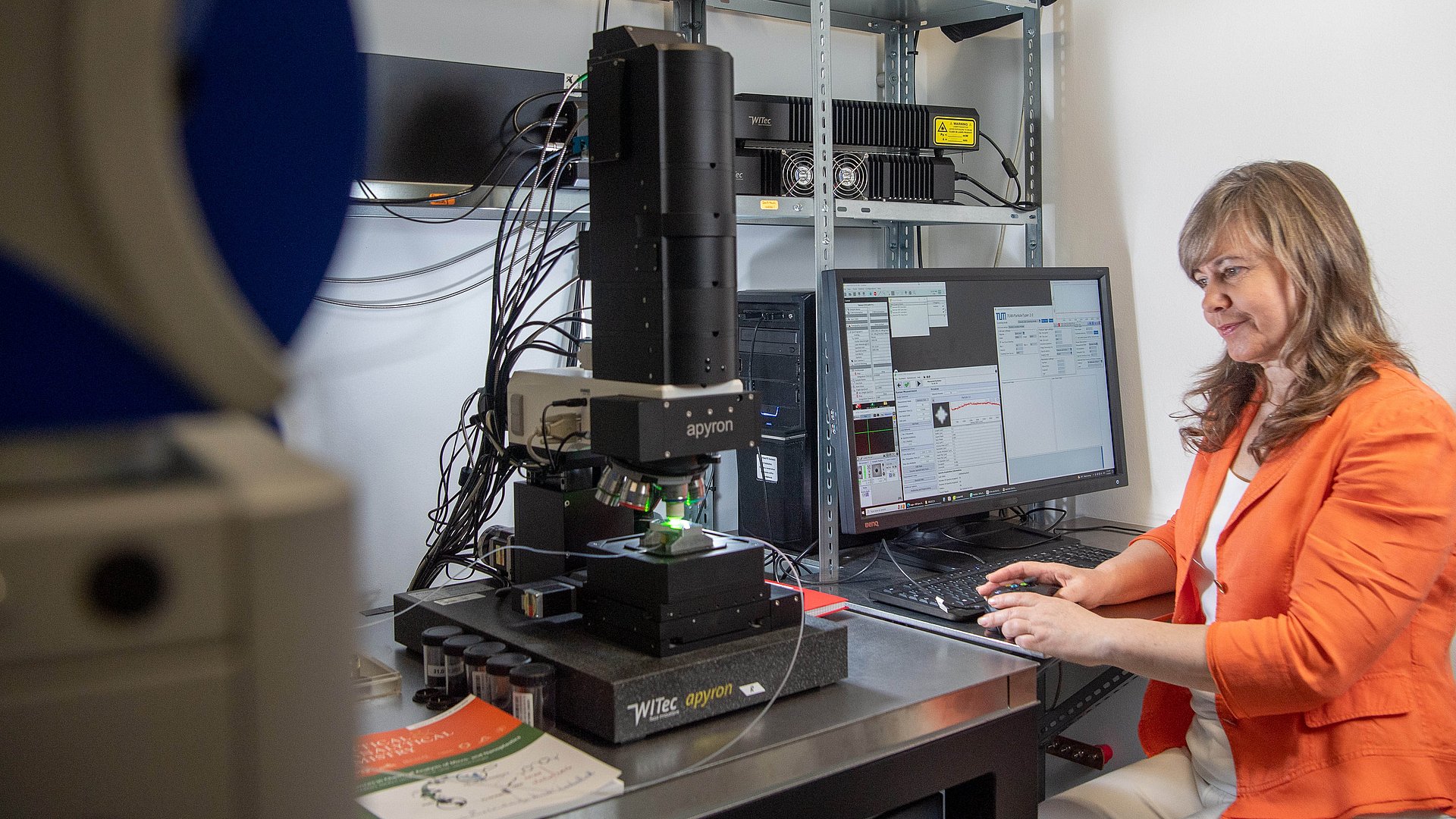

“Our approach is fundamentally different,” says Dr. Ivleva: “It is particle-based. That means that instead of destroying the particles, we analyze them directly.” To do this, the researchers use a method known as Raman microspectroscopy. It works by shining a monochromatic laser source onto a sample and detecting the light scattered by the molecules. Comparing the scattered light against the laser source provides information on the substance under investigation. To analyze plastic particles with a diameter greater than 1 µm (micrometer), they must first be filtered out of the aqueous solution, detected under the microscope and then illuminated with laser light. Because plastics such as polyethylene, polystyrene and polyvinyl chloride scatter the photons in characteristic ways, they each generate signals as unique as a fingerprint.

Automation instead of manual measurements

It took years to develop the tracing process: “When we started, we still had to make manual measurements,” recalls the chemist. “It took us months to investigate a few thousand particles.” In the meantime the team has succeeded in automating the detection of microplastics. A single analysis no longer takes weeks, but only a matter of hours. Although the tiny particles still have to be filtered out of the aqueous solution, followed by placement of the filter under the Raman microspectroscope, all remaining steps are carried out by the software developed by the team. The plastic particles are first localized with a light microscope, photographed and measured, and the particles are distinguished from fibers. The software uses these data to compute the number of particles and fibers and to select the image sections needed for a statistically significant result in the subsequent Raman spectroscopy.

In the next step, the laser is directed onto the sample and the scattering is detected and analyzed. This allows quick and reliable analysis of the number, size, shape and composition of the microplastics. The open-source TUM-Particle Typer 2 software is now available to researchers around the world.

Nanoplastics require special detection processes

To investigate nanoparticles with diameters of less than 1 µm, however, Dr. Ivleva’s team is already working on a modified process. “Nanoparticles like these are difficult or even impossible to discern under a light microscope. To detect them, we first have to carry out size fractionation and then identify them,” explains the researcher.

For this purpose, a field flow fractionation (FFF) system is used. This creates a water flow that captures the particles – depending on their size – and separates them by transporting them at varying speeds. A specially developed device, combined with Raman spectroscopy, permits the chemical characterization of different types of nanoplastics.

“The new analytical processes permit rapid and precise investigation of concentration, size and composition of micro- and nanoplastics,” sums up Dr. Ivleva. “This will now make it possible to study the influence of these particles on the environment and human health.”

- Oliver Jacob, Alejandro Ramírez-Piñero, Martin Elsner, Natalia P. Ivleva, TUM-ParticleTyper 2: Automated Quantitative Analysis of (Microplastic) Particles and Fibers down to 1 μm by Raman Microspectroscopy, Analytical and Bioanalytical Chemistry

https://link.springer.com/article/10.1007/s00216-023-04712-9 - Maximilian J. Huber, Natalia P. Ivleva, Andy M. Booth, Irina Beer, Ivana Bianchi, Roland Drexel, Otmar Geiss, Dora Mehn, Florian Meier, Alicja Molska, Jeremie Parot, Lisbet Sørensen, Gabriele Vella, Adriele Prina‑Mello, Robert Vogel, Fanny Caputo: Physicochemical Characterization and Quantification of Nanoplastics: Applicability, Limitations and Complementarity of Batch and Fractionation Methods, Analytical and Bioanalytical Chemistry

https://link.springer.com/article/10.1007/s00216-023-04689-5

- The JPI Oceans HOTMIC (03F0851B) project by M.Sc. Oliver Jacob on automated Raman analysis of microplastics is funded by the German Ministry for Education and Research (BMBF). Coordination: Dr. Aaron Beck, GEOMAR Helmholtz Centre for Ocean Research Kiel.

- The Bio_Mem (KK 5141501CR0) project by M.Sc. Maximilian J. Huber on Raman analysis of micro- and nanoplastics received funding from the German Ministry for Economic Affairs and Climate Action (BMWK). TUM project partners: Dr. Karl Glas and M.Sc. Helge Oesinghaus (Chair of Food Chemistry and Molecular Sensory Science). Industry partners: Dr. Florian Meier and Dr. Thorsten Klein (Postnova Analytics GmbH).

Technical University of Munich

Corporate Communications Center

- Monika Weiner / S. Reiffert

- stefanie.reiffert@tum.de

- presse@tum.de

- Teamwebsite

Contacts to this article:

Dr. Natalia P. Ivleva

Technical University of Munich (TUM)

Tel: +49 89 289 54 507

natalia.ivleva@tum.de

https://www.ch.nat.tum.de/hydrochemistry